Materials Design’s State-of-the-Art Tools Supporting Tomorrow’s Energy Solutions: Controlled Fusion

- Katherine Hollingsworth

- Jan 19, 2023

- 3 min read

Updated: Jan 25, 2023

Fusion energy may be our planet’s best long-term solution to the existential threat of global warming. A recent breakthrough in fusion energy is raising renewed hopes that practical fusion power may be on the horizon. Controlled fusion, which produces no greenhouse gases, offers prospects for obviating the production of long-lived actinides and eliminating the threats of nuclear weapons proliferation and fission power plant accidents that have long plagued fission power technology. And yet, numerous technological hurdles lay on the path to fusion power’s engineering practicality, not the least of which are major materials performance challenges.

The Materials Design Contract Research Team is working with the United Kingdom Atomic Energy Authority (UKAEA), a world class center for research into thermonuclear plasma and the materials science, engineering and technology development needed to enable future fusion power plants. UKAEA’s main mission is to lead the delivery of sustainable fusion energy and to maximize its scientific and economic benefit. Materials Design is supporting UKAEA’s mission by providing urgently needed insights into the key problem of tritium containment. Tritium, a heavy isotope of hydrogen with a half-life of 12.32 years, is an essential ingredient for harnessing fusion energy, but it must be produced artificially by a separate nuclear process with its own complexities. These facts make it imperative to minimize the loss of tritium through the sides of the fusion device. By virtue of its high melting temperature, the “first wall” of the fusion device closest to the hot plasma where fusion takes place is made of tungsten. Important development challenges for this plasma-facing structural component are therefore to limit tritium absorption and sequestration therein, and to fully understand the oxidation kinetics of tungsten under first wall exposure conditions.

Figure 1: Tungsten oxide film on tungsten metal (gray) loaded with tritium (blue spheres)

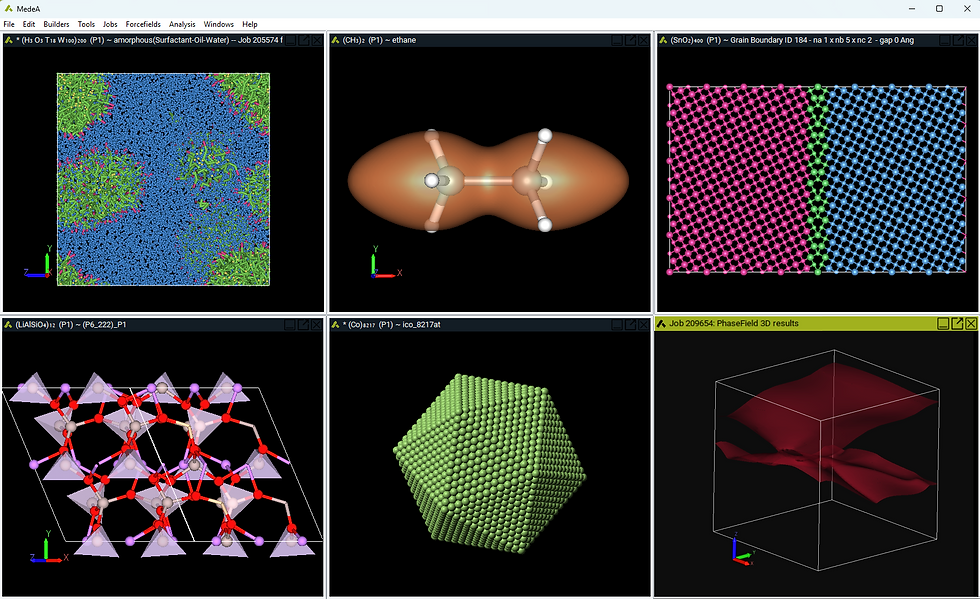

Materials Design’s sophisticated arsenal of computational tools is uniquely suited for addressing the complex problem of tritium mobility and trapping within the fusion device’s first wall. The VASP first principles computational software within the MedeA® computational environment is mapping the structural, thermodynamic, kinetic, and vibrational properties of the T-WOx system (x = 0 to 3), which determine tritium solubility and mobility in the sequence of defected WOx phases present between the fusion plasma and the first wall exterior. These same ab initio tools are populating large training sets for the development of state-of-the-art machine-learned interatomic potentials (MLPs) for high-temperature molecular dynamics simulations of tritium diffusion. Analyses to date have revealed that the various phases of the WOx system exhibit markedly different tritium insertion energies and diffusion energy barriers. These insights are expanding the previous understanding of tritium transport in tungsten and its oxides, which had focused primarily on the T insertion barrier at the W/WOx interface. Likewise, the vibrational modes being computed will aid in the interpretation of IR and Raman spectrum data and will help to positively identify all the oxide phases present in the first wall as well as the tritium binding sites.

“The new MLPs are definitive proof of the ease and efficacy of our brand new, highly automated MLP Generator (MLPG) module in MedeA, which enables the broad user community to take full advantage of state-of-the-art machine learned interatomic potential technology for the materials systems and properties of their choice,” says Dr. Erich Wimmer, Chief Scientific Officer of Materials Design. He added, “This unprecedented simulation technology is the fruit of an ongoing collaboration between highly talented and experienced scientists and software engineers in our company and leading academic and government research groups in Europe and America. These breakthrough advances are empowering our customers who are designing tomorrow’s energy solutions.”

Dr. Amanda Quadling, Director of Materials at the United Kingdom Atomic Energy Authority, stated, “We welcome what Materials Design will bring by way of its materials modeling technology. Fusion energy development is one of the greatest scientific and engineering challenges of our time.”

Related publications and materials:

UKAEA Publications: https://scientific-publications.ukaea.uk/,

Fusion and VASP methods: https://doi.org/10.1016/j.jnucmat.2022.154019 and MedeA VASP

Questions:

Materials Design, Inc.

Katherine Hollingsworth

Marketing and Communications Manager

United Kingdom Atomic Energy Authority (UKAEA)

Kelly Lea

Communications and Media Manager

#UKAEA #MedeA #fusion #MLP #tungsten #materialsdesign #ML #energy #sustainability #atomistic #simulation #tritium #fusionenergy #thermonuclear

#ComputationalDesign #materialdesign #materialsengineering #abinitio #materialscience #moleculardynamics #materialsscience #MaterialDesign #modelingandsimulation #modeling

Comments