Protecting the Environment with the Polymer Expert

- Katherine Hollingsworth

- Sep 9, 2024

- 2 min read

Updated: Nov 26, 2024

An enormous number of single use drinking straws are discarded every year.

The global drinking straw market is a good example for the replacement of plastic products by environmentally friendly alternatives. While the use of plastic straws has been banned in the EU in 2021 the global market is still valued at an astonishing 25 billion dollars per annum [1]. And ever since the 1960s, plastic has replaced paper as the optimum material from which to fabricate drinking straws because polypropylene is inexpensive and produces a robust product..

However, as is often the case, innovation leads to new problems, and this is certainly the case with polypropylene drinking straws. Polypropylene straws survive in the environment for decades, endanger wildlife, and eventually release harmful chemicals as they decompose.

So, this led to the EU ban and the search for alternatives. Fortunately, examining the characteristics of polymeric materials is where MedeA Property Expert excels [2,3]. As a swift illustration of the capabilities of Polymer Expert, consider the query shown below, which is based on the physical properties of polypropylene.

Defining the desired characteristics for possible polypropylene replacements

Using knowledge augmented machine learning, MedeA Property Expert takes supplied properties and provides candidate polymers which are capable of providing those desired characteristics.

The first and second hits are polypropylene and polyhydroxybutyrate (PHB) respectively, and polylactic acid is hit number 13.

The results returned by Polymer Expert are materials capable of yielding similar properties to polypropylene. Unsurprisingly, the first candidate is polypropylene itself. The second candidate is polyhydroxybutyrate (PHB). In fact, a variety of esters and ether based materials are among the top 25 repeat units provided by the Polymer Expert, and polylactic acid (PLA) is the 13th result. That polyhydroxybutyrate (PHB) and polylactic acid (PLA) are suggested by the Polymer Expert are also not surprises, both PHB and PLA are already used to manufacture drinking straws and command a substantial price premium relative to their polypropylene competitors, because consumers and governments are concerned about the environment. PHB and PLA based drinking straws completely decompose in about 100 days.

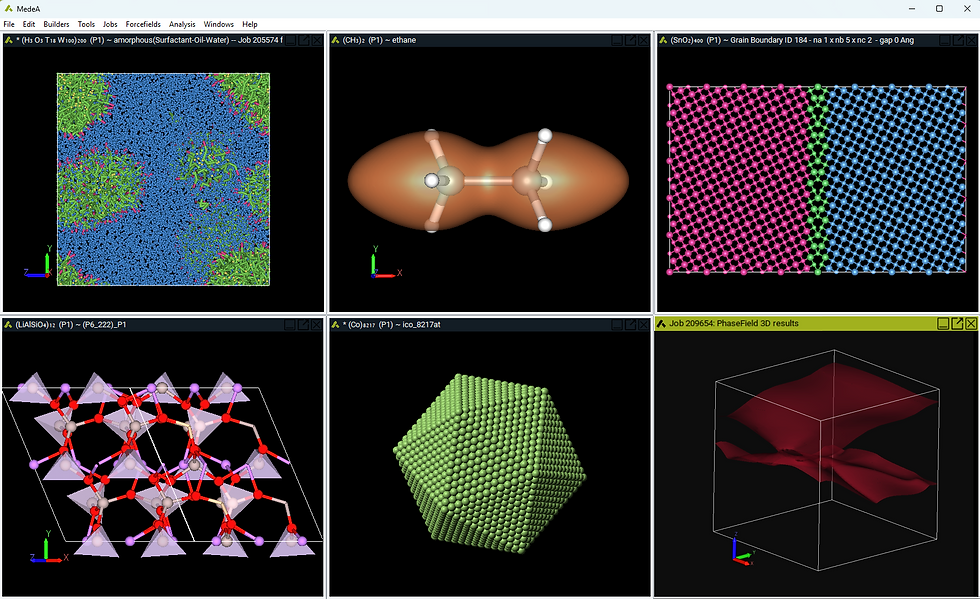

And once you have a lead, such as PHB or PLA, the MedeA Environment facilitates simulation of a wide range of properties, using atomistic simulation methods.

Polypropylene and polyhydroxybutyrate models in the MedeA modeling environment

For example, computing the cohesive energy density of these materials using the highly accurate PCFF+ forcefield and the MedeA LAMMPS interface is straightforward as illustrated above.

Designing and selecting new materials is an involved process, as any chemist, formulator, or process engineer can attest. However, the MedeA Polymer Expert, and the simulation tools of the MedeA simulation environment, allow you to innovate efficiently. If you are interested in learning more about property based repeat unit screening, using knowledge augmented machine learning, or any of the topics described in this article, please drop us a line at info@materialsdesign.com

References

#MaterialsScience #PolymerScience #MaterialsEngineering #SustainableMaterials #Polypropylene #Polyhydroxybutyrate #PolylacticAcid #GreenChemistry #MaterialInnovation #EcoFriendlyMaterials #MachineLearning #MaterialSimulation #PolymerExpert #ChemicalEngineering #EnvironmentalImpact #AtomisticSimulation #MaterialsDesign #AdvancedModeling #MLP #MedeA #MaterialDesign #compchem

Comments